Crawler Crane Market Analysis

Ⅰ Overview Introduction

Crawler crane is a full slewing jib crane with crawler traveling device, also known as crawler crane. It is mainly composed of power unit, transmission device, slewing mechanism, traveling mechanism, winch mechanism, operating system, working device and electrical equipment. Due to the large grounding area of the crawler, good passability and adaptability, it can walk with a load and is suitable for lifting operations at construction sites. It can carry out many kinds of operations such as digging, tamping, piling and so on. However, because of the slow walking speed, long-distance transfer site needs other vehicles to carry.

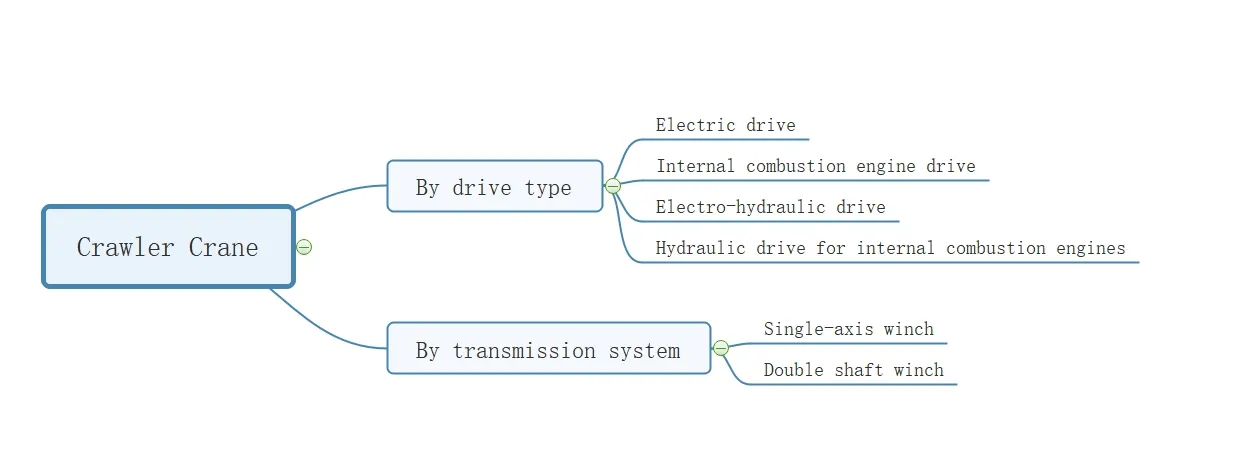

Crawler cranes can be divided into two categories of single-axle winches and double-axle winches according to the transmission system, and can be divided into four categories of electric drive, internal combustion engine drive, electric-hydraulic drive and internal combustion engine hydraulic drive according to the drive mode.

Ⅱ Industry chain analysis

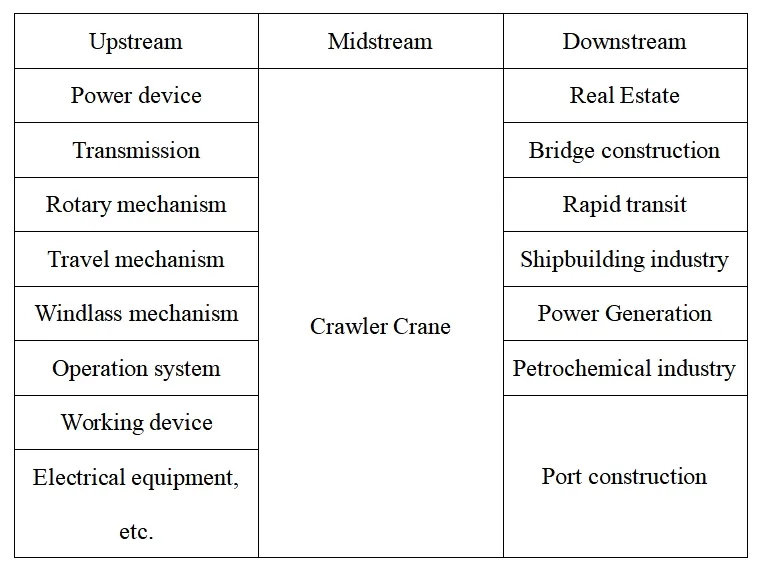

The upstream of the industry chain of crawler crane industry is the parts and components environment, mainly including the power unit, transmission, slewing mechanism, traveling mechanism, winch mechanism, operating system, working devices and electrical equipment, etc.; the middle reaches of the crawler crane production and supply chain; the downstream is mainly used in real estate, bridges, rail transportation, shipbuilding, power generation, petrochemical and other fields.

Ⅲ Crawler Crane Applications

Infrastructure projects often involve the handling of heavy materials and the installation of large components. Crawler cranes are capable of lifting exceptionally heavy loads, which makes them vital for such projects. Crawler cranes are versatile and can be used for a variety of applications in infrastructure development, including lifting bridge sections into place, pouring concrete sections for roads and highways, and handling large construction materials. Many infrastructure projects are located in rugged or uneven terrain, such as riverbanks, hilly areas or coastal areas. Crawler cranes' tracked undercarriage systems allow them to work on these challenging surfaces, allowing access to otherwise inaccessible locations. Infrastructure projects often require materials and equipment to be lifted to considerable heights or over obstacles. Telescopic boom crawler cranes perform particularly well in these situations. The stability of a crawler crane is crucial when working with heavy loads at height. The low center of gravity and wide footprint provided by the crawler gives it inherent stability, ensuring safety and precision.

Ⅳ Crawler crane market analysis

Crawler cranes are capital-intensive equipment and the cost of purchasing a new crawler crane can be high. This cost can be a major obstacle for small construction companies or contractors with limited financial resources. It may also deter potential buyers from entering the market. Many construction projects operate on tight budgets. When a large portion of the project budget needs to be allocated for the purchase of a crawler crane, it may limit the funds available for other capital project needs, which may affect the viability and profitability of the project. High upfront costs may make companies risk averse when considering the purchase of a crawler crane.

They may choose other alternatives, such as renting cranes on a project-by-project basis, to avoid a long-term financial commitment. Such options may limit the market growth of crawler crane manufacturers. Obtaining financing for crawler crane purchases can be challenging, especially for small businesses or startups. High interest rates or stringent lending standards may further deter potential buyers from investing in these machines. Like other heavy machinery, the value of crawler cranes depreciates over time. High depreciation rates can be a problem for companies looking to recoup their investment when reselling or trading in old cranes for newer models.

Advanced materials and engineering techniques allow crawler cranes to have higher lifting capacities. This makes them suitable for handling larger and heavier loads, which is vital for industries such as construction, mining and renewable energy. The integration of telematics systems allows for remote monitoring of the performance and health of the crane. This data-driven approach helps operators and maintenance teams make informed decisions to optimize crane operations and reduce downtime. Technological advances have led to improved safety features, including load monitoring systems, collision avoidance systems and real-time monitoring of crane stability. Enhanced safety not only reduces accidents, but also lowers insurance and liability costs.

Modern crawler cranes benefit from more efficient hydraulic systems, streamlined designs and better fuel economy. These efficiency gains can result in cost savings for crane operators. In response to environmental concerns and regulations, technological innovations have resulted in more environmentally friendly crawler cranes with reduced emissions and improved fuel efficiency. Automation and remote control features are becoming more prevalent in crawler crane technology.

These features can increase productivity, especially in applications that require precise and repetitive tasks. Innovations in control systems provide operators with greater precision and ease of use, which shortens the learning curve for crane operation. Advances allow for more modular and customizable crawler crane designs, enabling crane manufacturers to meet specific project requirements. Data analytics can be used to predict maintenance needs, reduce downtime and improve the overall reliability of crawler cranes. Continued research and development of telescopic boom designs allows for longer working ranges, faster extension/retraction and greater stability, extending the versatility of crawler cranes.

Chat Now

Chat Now