Gaodetec GGP300/300/75 PI-E Geotechnical Cement Grout Injection Station

GGP300/300/75PI-E

Specs & Compare

Details

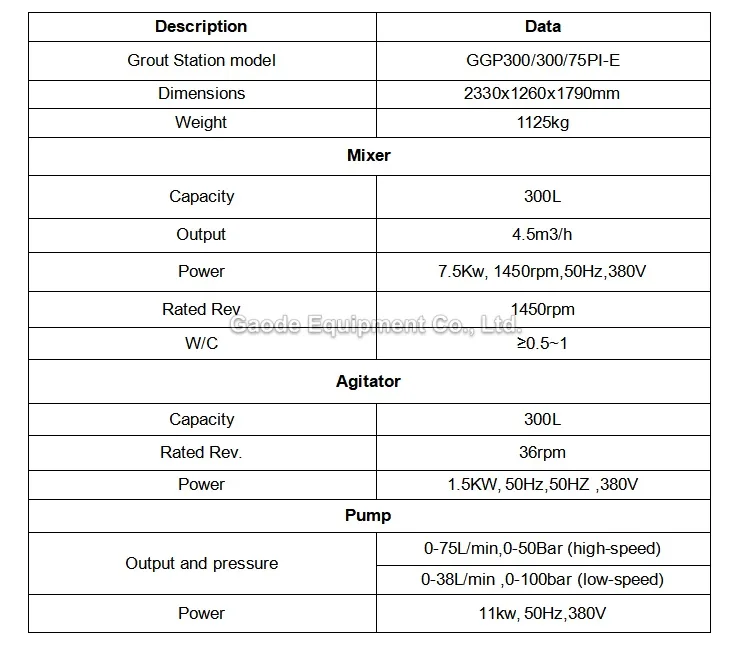

Specifications

- Weight:1125.000kg

- Grout Station model:GGP300/300/75PI-E

- Dimensions:2330x1260x1790mm

- Weight:1125kg

- Mixer Capacity:300L

- Agitator Capacity:300L

- Pump Power:11kw, 50Hz, 380V

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Supply Ability:10,000 Set/ Sets per Month

- Total Quantity In Stock:Over 5000

- Delivery Port:Any Port In China

Description

Gaodetec GGP300/300/75 PI-E Geotechnical Cement Grout Injection Station is a combination of mixer, agitator and grout pump in one plant. It is mainly used in highway, railway, hydropower, construction, mining and other ground and underground construction.

High speed vortex mixer ensures mix quickly and evenly. Water, cement and other media are quickly mixed into a homogeneous slurry. Then the mixed slurry was delivered to the agitator. Grout pump injects from the mixing drum (storage tank). This ensures a continuous mixing and grouting operations. The grouting pump is hydraulic drive. Grouting pressure and displacement is stepless adjustable. Compact size and it is easy to operate. It also takes up a small space.

The features and advantages of this machine are as follows:

Hydraulic reversing and Hydraulic drive for vertical grouting pump;

Grouting pressure and output are step-less adjustable;

Using rectangular agitator, makes the plant has compact structure, and small size;

With high speed and low speed, by rotating ball valve switch;

With function of record and display grouting pump reciprocating times by a counter;

High speed vortex mixer ensures mix quickly and evenly;

Mixer and agitator switch by using squeeze handle, it is safe, reliable and easy to operate;

The motor has an overload protection function. Hydraulic system with oil temperature overheating protection;

With CE, ISO certification.

Parameters

Details Images

Application

1. Civil Engineering - dam foundations, tunnels, mining, soil nails, tiebacks, earth anchors, cable and rock bolts.

2. Structural – building and bridge restoration, foundation stabilization, foundation raising, soil compaction grouting; soil & rock grouting.

3. Construction - pavement under sealing, slab jacking and slab raising.

4. Marine - underwater foundations, piers, breakers, shoreline foundations.

5. Mining - tunnel lining, contact grouting, shaft waterproofing.

6. Utilities - encasements, waterproofing, slope line grouting.

7. Geotechnical - deep well casing, monitor wells, well sealing and abandonment.

FAQ

1. Are you the manufacturer or a trade company?

We are the manufacturer for producing grout equipment.

And we have owned a trading company to do International Business,

So that:

1)-We can supply good service with professional international trade experience.

2)-The price is much more competitive.

2. Can you do the ODM or OEM? What is MOQ?

Yes, it is possible as discussed, MOQ: 1unit.

3. What about delivery time? How long can I get the machine after the order?

The production time is as fast as 30-60 working days if you customize the machine.

The standard machine in stock can be delivered as soon as possible after ordering.

4. How to pay for yourself?

50% down payment, then production starts, and the balance 50% paid before shipping.

If the machines are in stock, pay 100% then delivery.

Our Advantages

Packaging and Delivery

Contact Supplier

1. What is the project you are going to do?

2. What flow and pressure do you demand?

3. What's the water-cement ratio of the material you will mix and grout?

4. Regarding the engine, would you like an electric motor or a diesel engine? if electric motor, 3 phase, 380v, 50HZ is ok for you?

Certified for 3 years

Rating

Response Time

1 hour

Year of establishment

Founded in 2012, Gaode Equipment is a supplier with ISO 9001:2015 and CE certificate in the above products( grout equipment, hydroseeder, refractory equipment) in China. Whatsapp no.: +8615903656865

Company Address

ZhengZhou City, China. Any interest, please contact Whatsapp no.: +8615903656865

Add a Product

1 selected

Confirm