XCMG Official XR320E Second Hand Drilling Rig Rotary Pile Driving Machine Price

XR320E

Specs & Compare

Details

Specifications

- Weight:95000.000kg

- Year:2020

- Origin:Xuzhou, Jiangsu, China

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Delivery Port:Any Port In China

XCMG STORY

XCMG RECONDITIONED MACHINE

XCMG reconditioned machine is the second-hand machine program launched by XCMG for the

post market. XCMG takes advantage of its dealers network to collect the second-hand XCMG

machine that falls into strict standards: good condition, full function and low service hours. The

returned machine is then disassembled, repaired, painted, rebuilt and tested officially by XCMG,

and the product life is therefore extended. The price of XCMG reconditioned machine is far

lower than that of the new one, but its performance and safety are not compromised thanks to

XCMG's state-of-the-art processes and technologies. In order to dispel customers' concerns,

XCMG establishes a strict evaluation system for reconditioned machines and invites SGS to issue

third-party certification.

OUR TEAM

150+ SPECIALISTS

150+ specialists participate in the reconditioning process.

Inspection Team

Certified professional accessors who have worked for more than 10 years conduct comprehensive analysis on the machine.

Reconditioning and Repairing Team

Refurbish core parts to restore capacity. Replace all worn parts with genuine XCMG new ones.

Issuing Report Team

Certified examiner inspects, tests and certifies the reconditioned machine. SGS provides the third-party inspection certificate.

OUR FACTORY

REMANUFACTURING FACTORY

RECONDITION PROCESSES

RECONDITION PROCESSES OF THE USED

We maintain a meticulous and rigorous attitude toward quality, focusing on extraordinary creativity,

elaborate designs and exquisite craftsmanship.

COLLECTION

Examine the working conditions, conduct static and dynamic assessment on the used machine. Only machines with

light deprecation, low working hours and full functions can be collected.

INSPECTION

Certified professional accessors who have worked for more than 10 years conduct comprehensive analysis on the

machine. More than 300 details are checked and compared to XCMG standard. Recondition plan is then decided.

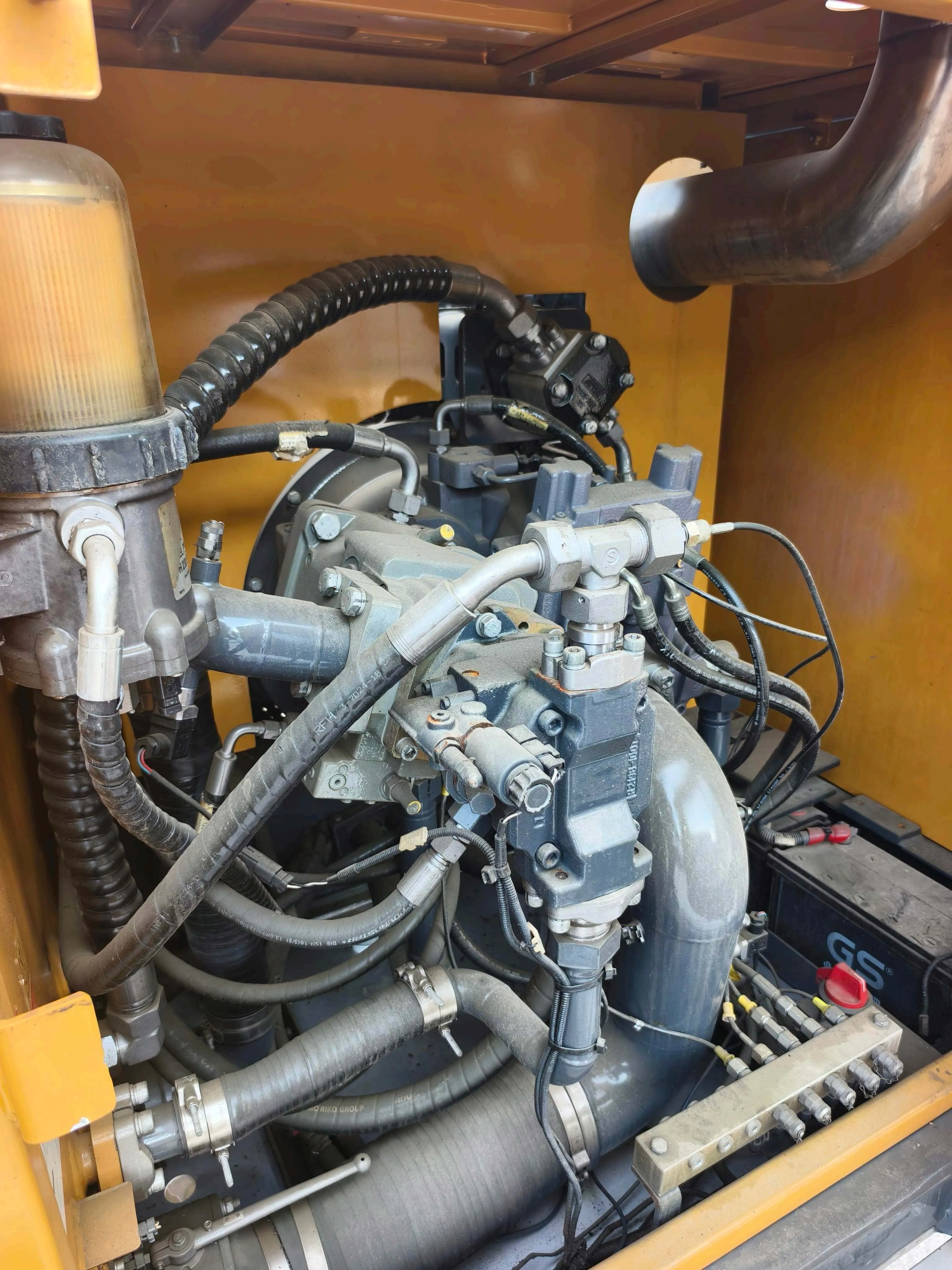

RECONDITIONING AND REPAIRING

Refurbish core parts to restore capacity. Replace all worn parts with genuine XCMG new ones.

TESTING

Follow the test procedure, ensure the performance and durability of the machine. Unqualified products are returned to step 3.

READY FOR DELIVERY

Ready for Delivery!!!

ISSUING REPORT

Certified examiner inspects, tests and certifies the reconditioned machine. SGS provides the third-party inspection certificate.

PAINTING

The whole machine is repainted to restore its appearance. Bright as new.

FAQ

FREQUENTLY ASKED QUESTIONS

1.What’s the warranty policy for XCMG reconditioned machines?

The warranty policy does not cover the covering parts and wearing parts. For engine, gearbox, hydraulic pump,

distriutor valve and electric system, the warranty period will be 3 months or 500 working hours whichever comes first.

If there is any problem within warranty period, XCMG will provide solutions accordingly.

2.How about the quality of your machine?

The procedure of recondition is taking the same criterion of brand new XCMG machines, therefore, quality of machines

will be guaranteed. They are ready to work for you and XCMG will provide test report from professtional institute.

3.Are you the original manufacturer?

Yes! XCMG is leading construction machinery industry in China and XCMG can provide a complete range of constrcution machineries.

4.Can you satisfy my special requirement?

As the manufacturer,XCMG will review the special requirement and recondition it as per request (if possible).

5.What is accpetable payment terms?

Usually XCMG will accept T/T before shipment or 100% Letter of Credit at sight.

If any other questions, please feel free to contact with us.

If any other questions, please feel free to contact with us.

Add a Product

1 selected

Confirm