Summary

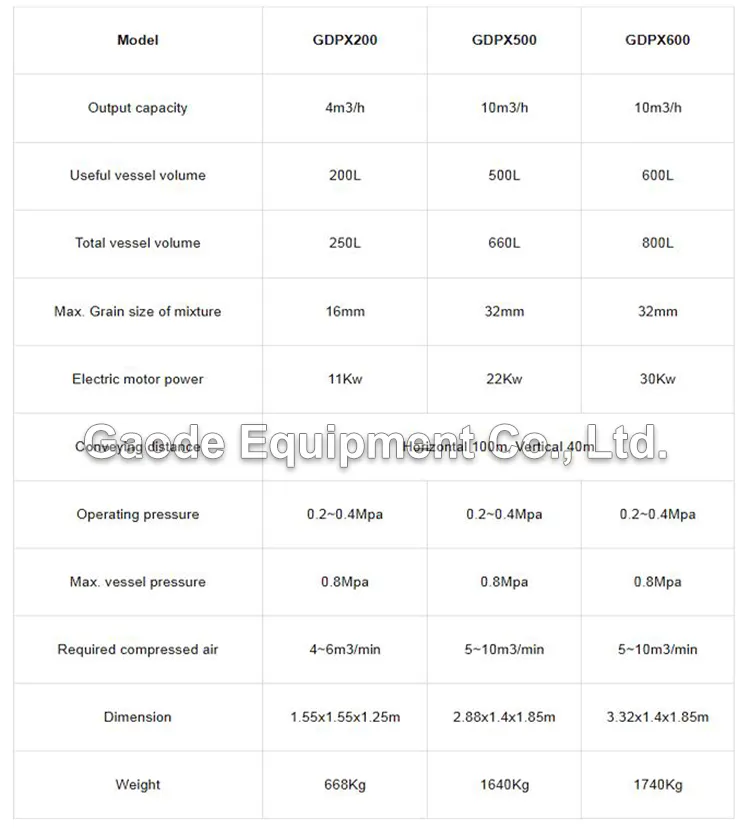

- Certification:CE

- Dimension(L*W*H):1.55x1.55x1.25m

- Weight:668~1740kg

- Power(W):11~30kw

- Voltage:380V,50Hz 3phase

- Model Number:GDPX

- Brand Name:Gaodetec

- Place of Origin:China

- Max Aggregate Size:16/32mm

- Max. Conveying Distance:Horizontal 100m, Vertical 40m

Specifications

- Weight:1740.000kg

- Useful volume of the hopper:4~10m³

- Useful vessel volume:200L/500L/600L

- Total vessel volume:250L/660L/800L

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Supply Ability:10,000 Set/ Sets per Month

- Total Quantity In Stock:Over 5000

- Delivery Port:Any Port In China

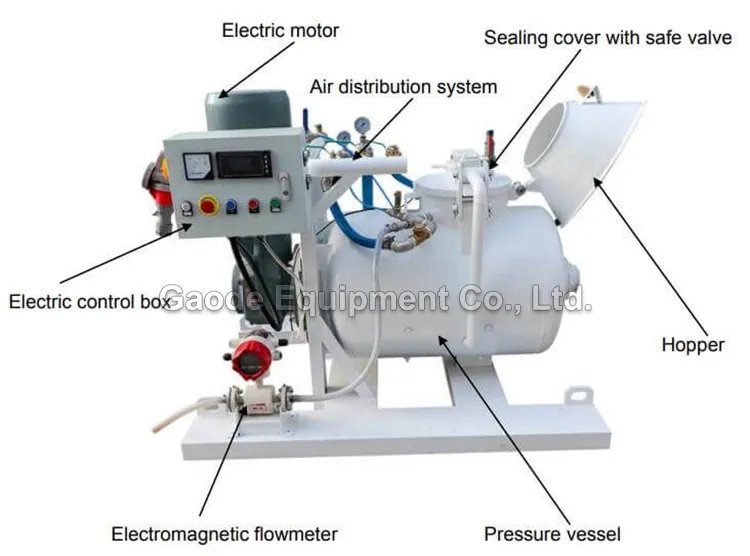

GDPx series refractory mixing and conveying unit is specially designed for conveying of solidand moistened mortar, concrete mixture and refractory castable. It is suitable for the using in themetallurgical industry produce permanent linings for ladles, tundish, blast furnace runners, onindustrial and melting furnaces for the glass and aluminium industry. The pneumatic refractorymixing and conveying unit can be used also in the building (construction) industry at the concreting of base of building, floors and larger concreted areas.

Working principle of refractory mixing and pressure conveying unit:Mixture closed in the pressure tank will be mixed by motion of mixing blades and by thecompressed air. Mixing blades slide simultaneously the mixture and push it into the dischargeport of the tank. Additional, lower position compressed air entering into the conveying hose andblow mixture uniform motion of in transport hoses. Transport of the mixture in the conveying hosepasses in agglomerates, and unique swirling air path design makes the materials will not producelarge fluctuations.

Our Advantages

.jpg.webp_l.webp)

.jpg.webp_t.webp)

.jpg.webp_t.webp)

.jpg.webp_t.webp)

.jpg.webp_t.webp)

.jpg.webp_t.webp)

.jpg.webp_t.webp)

.jpg.webp_t.webp)

_1753239476437.jpg.webp_t.webp)

.jpg.webp)