Gaodetec GGP250/350/100PI-D Industrial Colloidal Bentonite Cement Grout Station

GGP250/350/100PI-D

Specs & Compare

Details

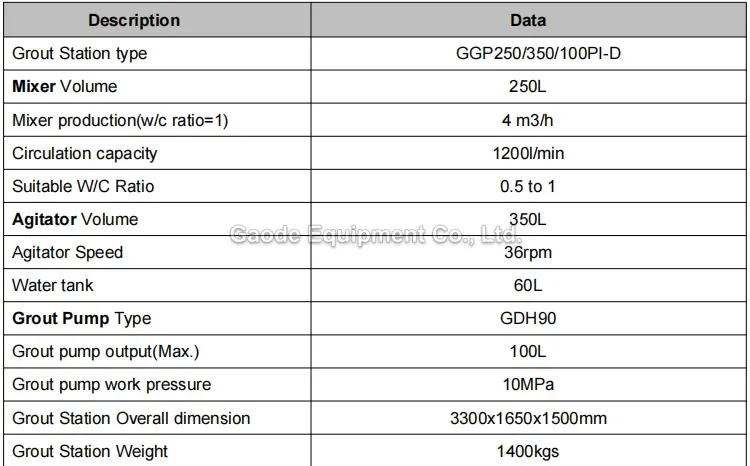

Specifications

- Weight:1400.000kg

- Grout Station type:GGP250/350/100PI-D

- Mixer Volume:250L

- Mixer production:4m3/h

- Circulation capacity:1200l/min

- Suitable W/C Ratio:0.5 to 1

- Weight:1400kg

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Supply Ability:10,000 Set/ Sets per Month

- Total Quantity In Stock:Over 5000

- Delivery Port:Any Port In China

Description

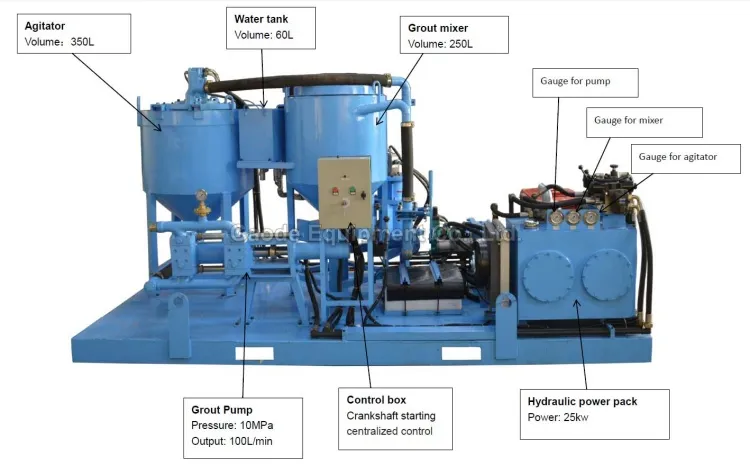

Gaodetec GGP250/350/100PI-D Industrial Colloidal Bentonite Cement Grout Station is a hydraulic driven combination of mixer, agitator and grout pump, it is specially design for continuous cement mixing and grouting in ground/underground engineering. It can fast mix water, cement and additive, then the mixed slurry can be stored into a 300 liters agitator, thus the mixing work can continuously be done.

This grout station can be used for grouting in soil, earth foundation stabilization, waterproofing, tunnel lining, underwater foundation, bridge decks, deep well casing, slope line grouting, etc.

The features and advantages of this machine are as follows:

1. Compact size, It is combination of mixer, agitator and piston grout pump in one base frame;

2. Yuken relief valve and directional valve for hydraulic system of grout pump;

3. Butterfly valve of mixer and agitator;

4. Oil temperature gauge can automatically control cooler fan working in normal temperature range, if temperature is too high, the machine will stop work automatically;

5. Operation and maintenance are simple;

6. With ISO, CE certificate.

Parameters

Details Images

Application

1. Civil Engineering - dam foundations, tunnels, mining, soil nails, tiebacks, earth anchors, cable and rock bolts.

2. Structural – building and bridge restoration, foundation stabilization, foundation raising, soil compaction grouting; soil & rock grouting.

3. Construction - pavement under sealing, slab jacking and slab raising.

4. Marine - underwater foundations, piers, breakers, shoreline foundations.

5. Mining - tunnel lining, contact grouting, shaft waterproofing.

6. Utilities - encasements, waterproofing, slope line grouting.

7. Geotechnical - deep well casing, monitor wells, well sealing and abandonment.

FAQ

1. Are you the manufacturer or a trade company?

We are the manufacturer for producing grout equipment.

And we have owned a trading company to do International Business,

So that:

1)-We can supply good service with professional international trade experience.

2)-The price is much more competitive.

2. Can you do the ODM or OEM? What is MOQ?

Yes, it is possible as discussed, MOQ: 1unit.

3. What about delivery time? How long can I get the machine after the order?

The production time is as fast as 30-60 working days if you customize the machine.

The standard machine in stock can be delivered as soon as possible after ordering.

4. How to pay for yourself?

50% down payment, then production starts, and the balance 50% paid before shipping.

If the machines are in stock, pay 100% then delivery.

Our Advantages

Packaging and Delivery

Contact Supplier

1. What is the project you are going to do?

2. What flow and pressure do you demand?

3. What's the water-cement ratio of the material you will mix and grout?

4. Regarding the engine, would you like an electric motor or a diesel engine? if electric motor, 3 phase, 380v, 50HZ is ok for you?

Certified for 3 years

Rating

Response Time

1 hour

Year of establishment

Founded in 2012, Gaode Equipment is a supplier with ISO 9001:2015 and CE certificate in the above products( grout equipment, hydroseeder, refractory equipment) in China. Whatsapp no.: +8615903656865

Company Address

ZhengZhou City, China. Any interest, please contact Whatsapp no.: +8615903656865

Add a Product

1 selected

Confirm