Summary

- Certification:CE

- Dimension(L*W*H):3000×1780×3250mm

- Weight:1635kg

- Power(W):13kw

- Voltage:380V,50Hz 3phase

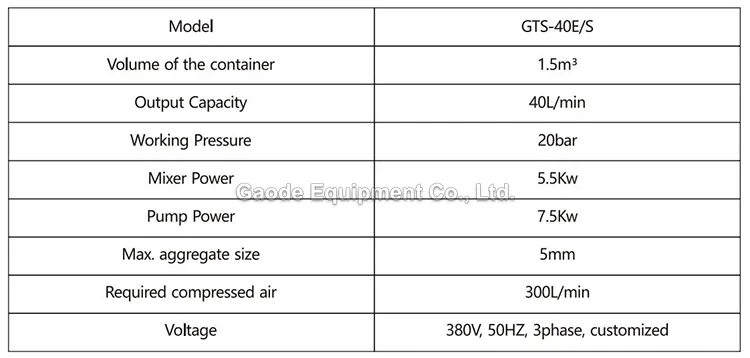

- Model Number:GTS-40E/S

- Brand Name:Gaodetec

- Place of Origin:China

- Hose Inner Diameter:32mm

- Max Aggregate Size:6mm

- Max. Conveying Distance:40 m

Specifications

- Weight:1635.000kg

- Useful volume of the hopper:1.5m³

- Mixing output:40L/min

- Conveying pressure:20bar, Max. 40 bar

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Supply Ability:10,000 Set/ Sets per Month

- Total Quantity In Stock:Over 5000

- Delivery Port:Any Port In China

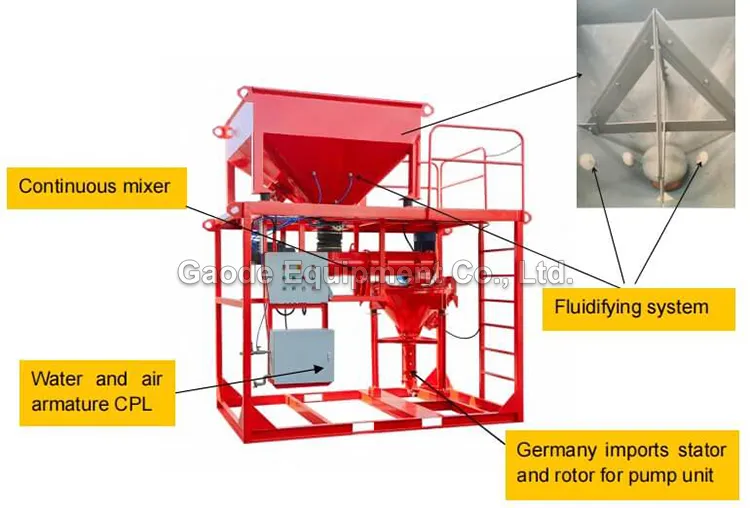

GTS-40E/S Tundish Spraying Machine is a highly developed combined mixing unit, pump unit and spraying unit for the spraying of refractory-slurry masses for Tundish-repair in steel mills. The combination of Ø250 continuous mixer and vertical screw pump 2L7 guarantees a homogenous mix of high quality refractory masses for efficient and utmost economical coating of Tundishes. This equipment is widely used in modern steel mills with continuous casting units to ensure undisturbed operation

Product features of GTS-40EIS Tundish spraying machine:

1.Frame

A steel frame with ladder, platform and rails detachable for transport herein included2.1500L Hopper

Dry mortar hopper with BIG-BAG-cutter detachable for transportBIG-BAG cutter

Fluidifying system on dry mortar silo with compressed air controlOLl Vibrator for dry mortar refractory hopper

3.Continuous Mixer

Transferring and stirring 2 parts

The mixing blade is made of wear-resistant steel and, which can easily replace the blade.GEKA quick connector (water filling port)

4.Pump Unit

Hopper with vibrator

Vertical mortar screw pump

Germany imports stator and rotor

Level probe for wet mortar hopper (Optional part)5.Control System (safe, and easy to operate)6.Water and Air Armature CPL

Air control :

Water control: for continuous mixer7.350L Water Tank (optional part)304 stainless steel water tank

A heating and pressurization systemGEKA quick connector

TS-40E/S Tundish spraying machine is used for iron and steel metallurgical industry:During the steel metallurgical process,Tundish is an important equipment connecting theconnected casting machine and steel water bag for storage and distribution of steel water. Toensure the quality of the steel water and the continuous casting process, the inner wall of themiddle bag needs to be scheduled regularly to prevent contamination or adhesion to preventdirect contact with the steel water and the wall of the bag. Therefore, the Tundish SprayingMachine is widely used in intermediate packaging operations in the steel metallurgical industry.

Our Advantages

.jpg.webp_l.webp)

.jpg.webp_t.webp)

.jpg.webp_t.webp)

.jpg.webp_t.webp)

.jpg.webp_t.webp)

.jpg.webp_t.webp)

_1753237371453.jpg.webp_t.webp)

_1753237372259.jpg.webp_t.webp)

.jpg.webp)